Back Pressure Turbine

Back pressure unit is a unit of combined heat and power production (cogeneration) operation, cogeneration can make rational use of energy, is an important measure to save energy. In many turbine generator sets, the back pressure machine is the highest in terms of thermal cycle efficiency because it eliminates the cold source loss of the condenser, thus reducing the coal consumption of power generation and saving energy, so it is widely used.

However, the back pressure machine also has the following disadvantages: its adaptability to load changes is poor, and the generation capacity of the unit is subject to heat load changes. When the heat load is low, the efficiency of the turbine decreases, thus reducing the economic benefit

- Information

A turbine whose exhaust pressure is greater than the atmospheric pressure is called a back pressure turbine. Exhaust steam can be used for heat supply or supply the original medium and low pressure steam turbine to replace the medium and low pressure boiler in the old power plant. When the back pressure steam turbine is used to supply the original medium and low pressure steam turbine to replace the medium and low pressure boiler in the old power plant, it is also called the front-loaded steam turbine, which can not only increase the power generation capacity of the original power plant, but also improve the thermal economy of the original power plant. The design value of exhaust steam pressure of back pressure turbine for heating depends on different purpose of heating. The back pressure of a front-mounted turbine is often greater than 5 mpa, depending on the steam parameters of the original unit. After the exhaust steam is used in the heating system, it condenses into water and is then sent back to the boiler by the pump as feed water. The condensate of the general heating system can not be fully recovered, and it is necessary to supplement the water supply.

The electric power emitted by the pressure turbine generator set is determined by the thermal load, so it can not meet the needs of both thermal and electrical load. The back-pressure steam turbine is generally not installed separately, but runs side by side with other condensing steam turbines, and the condensing steam turbine bears the change of electrical load to meet the external needs of electrical load. The electric power of a front-mounted turbine is determined by the amount of steam required by the medium and low pressure turbines. The pressure regulator is used to control the inlet steam volume to keep the exhaust steam pressure unchanged. The low pressure unit adjusts its own steam intake according to the need of electric load, so as to change the exhaust steam of the front-loading turbine. Therefore, the intake of steam can not be controlled directly by the power load of the front-loading turbine.

Because the power generation of the heating back pressure unit depends on the heat load, it is suitable for the occasions where the heat load is relatively stable, otherwise it should use the regulated extraction steam turbine.

The exhaust pressure of back-pressure steam turbine is high, the enthalpy drop of steam is small, and the condensing steam turbine with very low exhaust pressure produces the same power, and the steam required is large, so the steam required per unit power of back-pressure steam turbine is greater than that of condensing steam turbine. However, most of the heat contained in the exhaust steam of the back pressure turbine is used by the heat user, and there is no cold source loss. Therefore, from the point of view of the heat utilization coefficient of fuel, the thermal efficiency of the back pressure turbine is higher than that of the condensing turbine. Because the back pressure steam turbine can pass through a larger steam flow, the first few stages can use larger blades, so the internal efficiency is higher than the high pressure part of the condensing steam turbine.

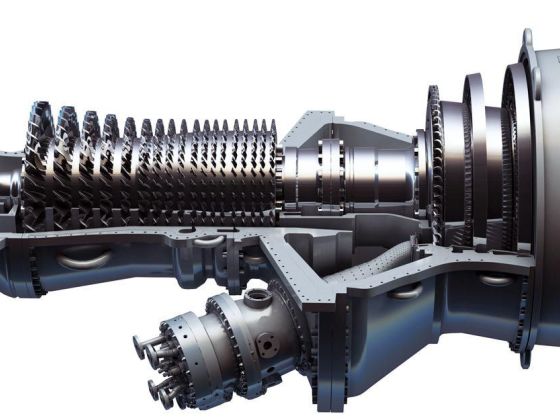

In structure, the high-pressure part of a back pressure turbine is similar to that of a condensing turbine. In order to ensure that the efficiency does not change much when the working condition changes, the back pressure turbine mostly adopts the nozzle regulating steam distribution mode. Because the back press is often used in the case of stable heat load, a single impulse stage is generally used as the regulating stage.