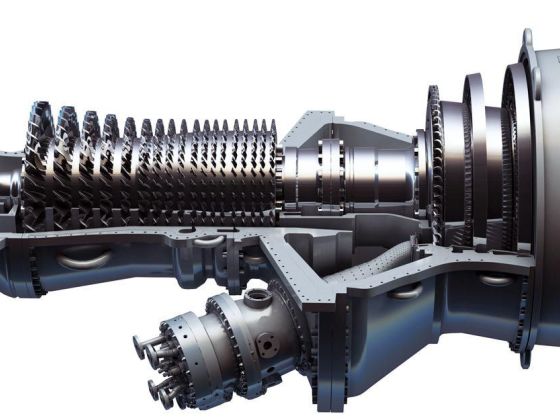

Intermediate Reheat Turbine

Intermediate reheat turbine is the steam in the steam turbine to do a part of the work, from the middle out, through the boiler reheater to increase the temperature (generally increased to the rated temperature of the unit), and then back to the steam turbine to continue to do work, and finally discharged into the steam turbine of the condenser. The steam is reheated in the middle, which not only reduces the exhaust humidity of the steam turbine, but also improves the working conditions of the last stage blades of the steam turbine and improves the relative internal efficiency of the steam turbine.

- Information

If the dynamic corrector is in a normal working state, the specific working process of this adjustment system is: if the external load is increased, the speed of the unit will be correspondingly reduced, at this time the primary oil pressure will be reduced, and the secondary oil pressure will be correspondingly increased. When the secondary oil pressure is applied to the dynamic corrector, a dynamic correction increment is generated on it, which will correct the oil pressure output. The positive oil pressure will increase the speed of the relay piston on the high pressure cylinder oil motor, and will also reduce the gap of the butterfly valve that controls the three times oil pressure, and the three times oil pressure will increase. Thus, the piston of the high-pressure cylinder oil motor begins to move up, and the wrong throttle slide valve moves down, at this time, the high-pressure cylinder adjustment valve will be quickly opened, and the power emitted by the unit will increase accordingly until it ADAPTS to the external load requirements. In this process, not only the dynamic correction oil pressure continues to decrease until it is equal to the secondary oil pressure, but also because the oil motor is moving upward and is affected by the lever feedback, the piston of the relay will slowly rise until the new load and the secondary oil pressure are stabilized at the corresponding static working point, and the entire adjustment process will be completely ended. If the external load is reduced, the action flow of the regulating system is just the opposite of the above