- Home

- >

- Products

- >

- Condensing Turbine

- >

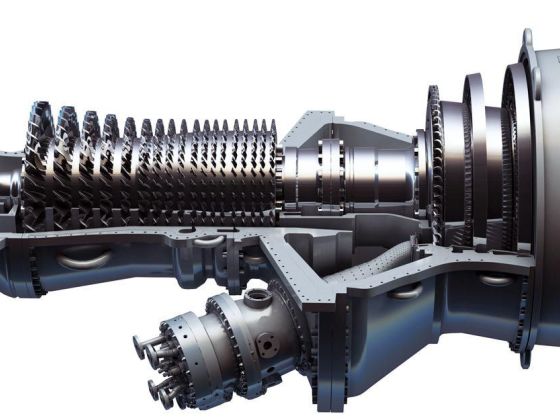

Condensing Turbine

The exhaust pressure of condensing steam turbine has obvious influence on the operation economy. The main factors affecting the vacuum degree of condenser are the inlet temperature of cooling water and the cooling rate. The former is related to the region, season and water supply mode of the power plant. The latter represents the ratio of the design flow of cooling water to the exhaust volume of the turbine. The cooling rate is large, and the high vacuum degree can be obtained. However, the increase of cooling ratio increases the power consumption and equipment investment of circulating pump. The cooling ratio of general surface condenser is designed to be 60 ~ 120. Due to the great demand of condensing turbine circulating water, water source condition becomes one of the important conditions for power plant siting.

Ideally, the condensate temperature of the surface condenser should be the same as that of the exhaust steam, and the heat taken away by the cooling water is only the latent heat of the exhaust steam. However, in actual operation, due to the existence of exhaust flow resistance and non-condensing gas, the condensate temperature is lower than the exhaust temperature, and the temperature difference between the two is called the degree of supercooling. Improper layout of cooling water pipes, high condensing water level in operation and soaking cooling water pipes will increase the degree of over-cooling. Under normal conditions, the supercooling degree should not be greater than 1 ~ 2℃.

- Information

Condensing steam turbine refers to a steam turbine in which the steam expands and does work in the steam turbine, except for a small part of the shaft seal leakage, all enter the condenser and condense into water.

In fact, in order to improve the thermal efficiency of the steam turbine and reduce the diameter and size of the exhaust cylinder of the steam turbine, the steam that has done some work is extracted from the steam turbine and sent to the reheating heater to heat the boiler feed water, which is not adjusted to extract steam turbine, also known as condensing turbine. A steam turbine commonly used in thermal power plants for generating electricity. Condensing equipment is mainly composed of condenser, circulating pump, condensate pump and air extractor. The exhaust steam of the turbine enters the condenser, is cooled by the circulating water and condensed into water, is drawn out by the condensate pump, and is heated by the heater at all levels and sent to the boiler as water supply.

When the exhaust steam of the steam turbine condenses into water in the condenser, the volume suddenly shrinks, so that the closed space filled with steam forms a vacuum, which reduces the exhaust pressure of the steam turbine and increases the ideal enthalpy drop of the steam, thus improving the thermal efficiency of the device. The non-condensing gas (mainly air) in the exhaust steam of the turbine is extracted by the extractor to maintain the necessary vacuum degree.