Extraction Back Pressure Turbine

Compared with ordinary steam turbines, extraction back pressure steam turbines have the following energy-saving advantages:

1. The exhaust steam is extracted by the air pump and then returned to the low pressure part to release heat energy, which improves the efficiency of the turbine.

2. The steam flows back to the boiler after releasing heat energy, forming recycling, reducing energy waste and environmental pollution.

3. The extraction back pressure steam turbine has a strong ability to adapt to load changes, and can achieve rapid response to ensure the stability and reliability of the power system.

- Information

Extraction back pressure steam turbine is a typical thermal steam turbine, its working principle and structure are very characteristic.

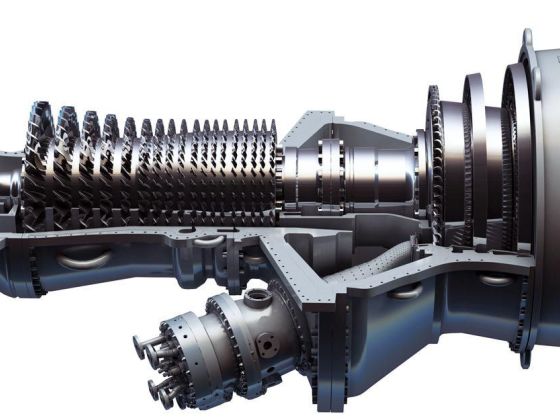

The structure of a back-pressure extraction steam turbine is mainly composed of an intake chamber, a nozzle, a cylinder, a turbine, a diffuser and an exhaust chamber. Among them, the intake chamber is used to guide high-temperature and high-pressure steam into the turbine, and the nozzle converts the pressure of the steam into kinetic energy to promote the turbine rotation. The cylinder and turbine are used to increase the kinetic energy and pressure of the steam, so that it is discharged at a higher pressure and temperature in the exhaust chamber.

The working principle of the extraction back pressure turbine is very unique. The steam goes through a series of conversion processes in the turbine, first entering through the intake chamber, then expanding in the nozzle to push the turbine to rotate. The steam then continues to expand in the cylinder, reducing the pressure and lowering the temperature. Finally, the steam is discharged in the exhaust chamber, and its pressure and temperature are increased. This working process makes full use of the steam energy and improves the efficiency of the turbine.

The advantages of extraction back pressure turbines are their high efficiency, stability and environmental protection. First, because of its unique working principle, this turbine is able to make full use of the energy of steam, thereby increasing efficiency. Secondly, its structure is stable, long life and less maintenance, which further improves its operating efficiency. Finally, the exhaust gas from the extraction back pressure turbine meets the environmental protection standard and has little impact on the environment.

Extraction back pressure steam turbines are used in a wide range of scenarios. For example, it can be used in electricity production, as a power source for large or small power facilities. In addition, it can also be used in industrial production areas such as chemical plants and paper mills to power production lines. At the same time, because of its efficient energy utilization and environmental protection characteristics, extraction back pressure steam turbines are also widely used in urban heating and other public services.

In general, extraction back pressure steam turbine is a kind of efficient and stable thermal steam turbine, which has unique working principle, stable structure, good environmental protection characteristics and wide application scenarios.