- Home

- >

- Products

- >

- Reaction Turbine

- >

Reaction Turbine

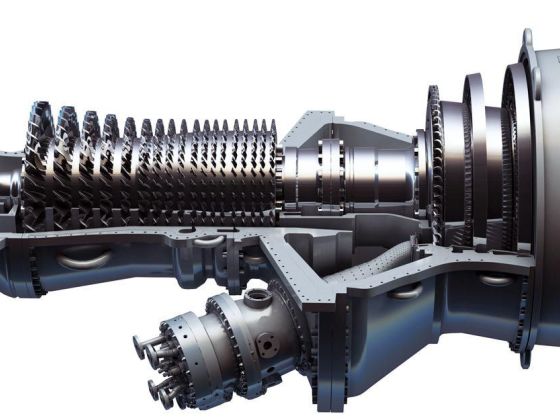

In contrast to the impulse type, the reaction turbine has more stages than the impulse type when the total power is the same, but the efficiency is higher. Since the steam continues to expand in the reaction cascade, there is a pressure difference on both sides of the dynamic cascade, so the reaction stage can not be partially admitted, so the first stage of the reaction turbine (that is, the regulation stage) is usually an impulse stage or a velocity stage: In terms of structure, due to the pressure difference on both sides of the dynamic cascade of the reaction stage, in order to avoid excessive axial thrust, the drum rotor is generally used, which can also reduce the axial size of the unit: in addition, the rotor of the reaction turbine is generally equipped with a balance disc to balance part of the axial thrust.

- Information

In a reaction turbine, the steam not only expands and accelerates in the nozzle, but also continues to expand and accelerate when it flows through the passage of the moving blade, that is, the steam in the moving cascade not only changes the direction of the steam flow, but also increases its relative speed. Therefore, the moving blade is not only affected by the impact force of the high-speed steam flow at the nozzle outlet, but also by the reaction force when the steam leaves the moving cascade, that is, the reaction turbine uses both the impulse principle for work and the reaction principle for work

Reaction steam turbines are generally multistage. According to the classification of steam flow direction in the turbine, the reaction turbine can be divided into two types: axial flow and radial flow.

Axial flow

The dynamic blades of axial flow multistage reaction turbine are directly installed on the drum, and static blades are installed in front of each row of blades. The section shape of moving blade and static blade is basically the same. After the new steam with pressure p0 enters the turbine through the annular chamber, it expands in the first stage stator cascade, the pressure decreases and the speed increases. Then it enters the first stage moving cascade, changes the flow direction, and generates impulse force. In the moving cascade, the steam continues to expand, the pressure drops and the flow rate increases. The increase of the speed of steam flow in the moving cascade produces the reverse force to the moving cascade. The rotor rotates and works under the combined action of impulse force and reaction force. The steam from the first stage enters the subsequent stages and repeats the above process until it exits the turbine through the last stage of the rotor cascade. Since the specific volume of steam increases with the reduction of pressure, the height of the blade increases accordingly, so that the flow area increases step by step to ensure the smooth flow of steam. Because of the pressure difference before and after each stage of a reaction turbine, a large axial thrust is generated on the whole rotor. In order to reduce the axial thrust, the reaction steam turbine can not use the impeller structure like the impulse steam turbine, but the balance piston is installed in the front of the rotor to offset the axial thrust. The space in front of the piston is connected by the connecting tube and the exhaust tube to generate a left axial thrust on the piston to achieve the purpose of balancing the axial thrust of the rotor.

Radial flow

The radial multistage reaction turbine has two axes, the impeller is respectively installed on the two rotating axes, and the blade is vertically installed on the end face of the two impels to form a moving cascade. The new steam enters the steam chamber from the new steam pipe, and then expands gradually through the dynamic cascade at all levels. The steam flow is used to push the impeller to rotate and do work, thus converting the heat energy of the steam into mechanical energy. The two rotors of the radial flow turbine rotate in opposite directions and can drive two generators respectively.